justin

Junior Member

Posts: 60

|

Post by justin on Oct 14, 2016 22:24:58 GMT -5

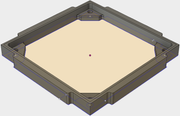

hello all, i wanted somewhere to document some of the modifications i plan to do to two br909's i've just purchased. these sets have firmware installed that has the rear fans run at full noise from power up. i understand that simply flashing them with the cinemax/cine 9 firmware will reduce fan noise and i plan to do that, but wanted to replicate what barco did with the cinemax/cine 9's sound baffle on my cnc hobby machine.  ^ on fusion 360 i drew this for machining. it's a close replicate of barco's fan shroud. i only have a 6mm wide cutting bit, so the bolt holes are 2mm wider.  ^ out of some mdf (cheap wood) i had laying around the garage i test cut the drawing to confirm measurements. it's perfect.  ^ the wood is weak and the narrow wall is flexible. i plan to machine the final parts from billet alumnium, so this will not be a problem.  ^ with no nuts fitted, i test fit to make sure everything lines up. perfect!   i also have drawings for a two part board to cover the rear perforated grill to reduce noise further. i made a bracket to relocate the power filter where barco have it on the cinemax/cine 9's. i will post pictures as the parts are completed. regards, justin. |

|

|

|

Post by hulio on Oct 15, 2016 8:34:29 GMT -5

Nice, Justin. Keep us updated.

|

|

|

|

Post by gjaky on Oct 15, 2016 12:05:59 GMT -5

I'd not recommend to replace that part with aluminium, fan holders are better to be made of some soft material so they are not transferring vibrations to the chassis.

|

|

|

|

Post by Casethecorvetteman on Oct 16, 2016 8:01:18 GMT -5

I'd not recommend to replace that part with aluminium, fan holders are better to be made of some soft material so they are not transferring vibrations to the chassis. Yeah and while i agree, the Cine 9 has those parts made of aluminium, and the fans are hard bolted in place. The 909 has the fans mounted with rubber pieces on my 2006 unit. |

|

justin

Junior Member

Posts: 60

|

Post by justin on Oct 16, 2016 16:42:47 GMT -5

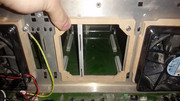

the only material that I could comfortably machine other than wood and aluminium is perspex or hdpe. these are both somewhat hard plastics?  this is the cine 9s fan shroud mounted. barco used two small rubber bits to absorb vibration. they sit 2mm~ off the chassis? the 909 as casey said uses a rubber bolt to hold them about the same distance away from the chassis. my 909 rubber bolts are tired. I will order some hdpe and see how it turns out. should machine okay. |

|

|

|

Post by Casethecorvetteman on Oct 17, 2016 2:18:39 GMT -5

I thinks its more an effort to make the fans draw more air from where theyre meant to pull it from more so than quiet things down, although in doing so, a better seal around the edge should reduce the noise due to not pulling air through the small gap around the edges.

|

|

justin

Junior Member

Posts: 60

|

Post by justin on Oct 30, 2016 19:50:49 GMT -5

small update. i redesigned the original drawing. the reason for this was the material i decided to use for the final parts is wood. the original drawing had thin walls. barco used aluminium and its far more rigid than wood. after a few test cuts, i was happy with my final design:  ^ each fan baffle has its own drawing unique to its surroundings. the pcb's clip into the aluminium near the fan mounts and create protrusions that prevent a flush fit with my original drawing. i now have cutouts to prevent this and now get a perfect seal on every fan mount! all thats left to do is mount these with some rubber nuts i found from a local supplier:   ^ these are very similar to what barco used on the cinemax/cine 9's. this will allow for some vibration absorption and easy dis/mounting of the fans for servicing when required.

^ these are just sitting freely. i have not purchased the rubber nuts yet. my next part to machine is a split rear baffle for the perforated grill on the back panel. |

|

|

|

Post by Casethecorvetteman on Oct 31, 2016 1:06:24 GMT -5

Very nice work mate! Should have some effect

|

|

justin

Junior Member

Posts: 60

|

Post by justin on Oct 31, 2016 17:18:35 GMT -5

thanks case. im sure it will yield some type of improvement? i was going to do a side by side audio recording of a stock 909 and my acoustically modified 909 before firmware flashing to get an idea of improvement. not sure if i can capture this accurately however, as all i have to record with is a mobile phone. hearing it with my own ears will be the true result as i eventually plan to sit underneath them. i did try other materials with the new drawings. one of them was hdpe and was horrible to machine. it required cleaning which i didnt like, unlike wood. wood machines nicely. i setup the cam speeds for my block of billet aluminium in fusion 360 and it was estimating 65min runtime... per baffle! and i need 6... at those speeds, no thanks  the stock i had was 20mm thick as it was all i have laying around spare. if i had 12mm thick stock, it may half the time. but as suggested above, wood has some absorption properties that aluminium does not. i'll be machining the rear plates today sometime from spare wood i have laying around. however i dont have bolts thin enough to pass through the holes of the grill to hold them up. anyway, i will report how it turns out later tonight... |

|

justin

Junior Member

Posts: 60

|

Post by justin on Nov 1, 2016 1:29:53 GMT -5

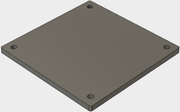

i got lazy. i have three designs for a rear baffle similar to the cinemax/cine 9. the easiest was this drawing:   ^ the plan is to mount this backing plate to the rear section of the fan. studying what barco did on the cinemax/cine 9, they only tried to block direct fan exhaust into the rear perforated grill... i am optimistic that this will achieve similar results? i will use a spacer between the plate and the fan on each bolt hole. i will fire the set back up once everything is fitted. |

|

|

|

Post by Casethecorvetteman on Nov 1, 2016 7:57:30 GMT -5

Not quite sure but seems like youre saying mount that straight behind the fan to block air going directly out the rear?

Itll take more than that.

|

|

justin

Junior Member

Posts: 60

|

Post by justin on Nov 1, 2016 15:23:50 GMT -5

I reread what I wrote and it does sound confusing. sorry!

yes, youre right. I wanted to mount it directly behind the fan (about 25mm away) to deflect the air.

after some more thought I will go back to the drawing board on this. I didnt like the way I had to mount this backing plate to the fan, either... its too fiddly.

I dont want to drill out the box on the back of the 909 (I dont want to drill or cut anything really), but it would be so much easier if I did.

|

|

justin

Junior Member

Posts: 60

|

Post by justin on Nov 2, 2016 1:53:14 GMT -5

|

|

|

|

Post by Casethecorvetteman on Nov 3, 2016 6:48:39 GMT -5

Looks reasonably simular to what i remember being in the Cine 9 mate yeah

|

|